Supporting materials

Download

Download this article as a PDF

Fabrics are not just for fashion: explore the processes materials science engineers use when selecting fabrics by designing a parachute.

Have you ever wondered who designs an astronaut’s space suit, a diver’s wetsuit, or even a parachute? The creators of this essential equipment are materials science engineers. Using next-generation science standards to frame materials science lessons allows students to make connections between content and what scientists do to investigate the world around us.[1] Introducing materials science in middle schools is a great way to provide career awareness in this field and to engage students in chemistry when going deeper into the physical properties of a particular material, such as ceramics, glass, metal, or even fabrics.[2,3]

By definition, fabric material is a piece of cloth. However, to a materials science engineer, fabric material is composed of synthetic or natural strands of fibre weaved together tightly or loosely in a pattern to form a piece of cloth. Fabrics are not commonly thought of as products materials science engineers would use, because they are materials mostly used by regular consumers to design clothes, cover furniture, or to decorate homes. Students will find interesting the level of detail materials science engineers use to select a fabric when designing an effective parachute as they begin a series of tests.

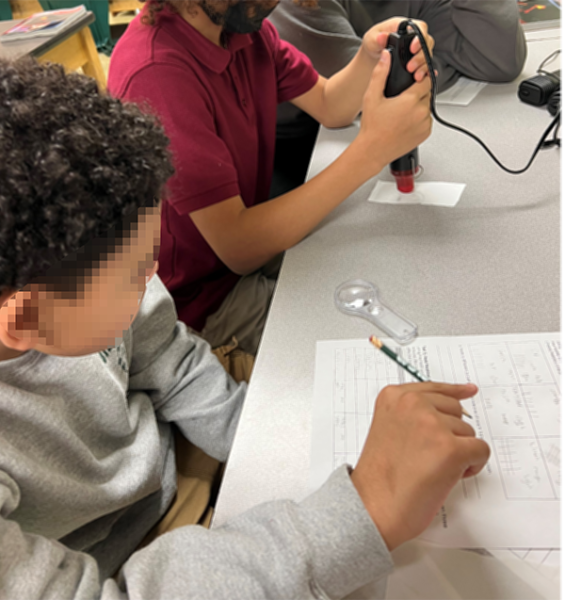

Students explore the properties of different fabrics. In these tests, each fabric is tested for durability and resistance. Comparing and contrasting the quality of materials will determine if the fabric material selection meets the requirements for the parachute design. Both activities in this lesson can be completed within a 60-minute time frame, including discussion time. This lesson is appropriate for 11- and 12-year-old students studying chemistry. Students should work in groups of four or five.

Students will examine different types of fibres and determine which would make the best parachute. Opportunities to explore multiple fabric materials will lead to an understanding of how fabrics are chosen for parachute designs given to students. This activity will help students to think about selecting materials according to their properties, purpose, and resistance to allow them to make a final selection.

The fabrics given are just suggestions; teachers can include or substitute different fabrics, like wool. Additional tests can also be added if the students discuss them, for example, weighing a fabric piece of a particular size.

Safety glasses should be worn when using a heat gun, and the heat gun should be at least 2 cm from the fabric to prevent the heat gun from overheating. Caution should be taken when using the heat gun. Caution should also be taken when using coarse sandpaper, as it can scrape fingers.

Each group will need:

This materials science lesson is a great way to get students to think and discuss like materials science engineers. The following questions can be used to guide the discussion:

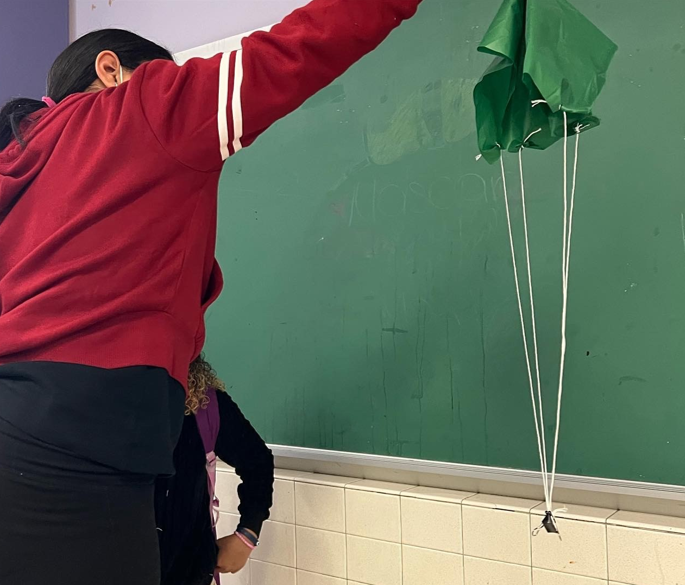

Based on the results of Activity 1, each group should choose a fabric to make a small parachute to test.

In this activity, students test the parachute performance of the fabric they chose in Activity 1. Teachers can discuss how research and preliminary experiments are important for guiding a design, but the next step is to make a prototype and test it, and this stage may reveal additional important factors that were not considered before.

Each group will need:

If two or more fabrics were selected, students compare and contrast their findings to decide which fabric material is the most suitable for the design of a parachute. If all students selected the same fabric, then a fabric piece that was not selected from Activity 1 should be tested to compare with the one selected. Some guiding questions are as follows:

This materials science lesson is a great way for students to think and discuss like materials science engineers. The discussion part is key. This lesson is not about getting the correct answers but learning how engineering (and science more generally) is done. It could be that properties not considered in Activity 1 (e.g. weight or stiffness) turn out to be very important for the wind performance. It should be made clear to students that it is not a failure if they do not pick the best-performing fabric. The experiment is considered a success when students are able to explain and support the subsequent step of development for their designs.

[1] Campbell T, Lee O (2021) Instructional materials designed for A Framework for K-12 Science Education and the next generation science standards: An introduction to the special issue. Journal of Science Teacher Education 32: 727–734. doi: 10.1080/1046560X.2021.1975359

[2] The standards used for the design of this lesson: https://www.nextgenscience.org/sites/default/files/MS.SPM 5.21.13with footer.pdf

[3] Nadelson LN, Moll AJ, Seifert AL (2011) Living in a materials world: Materials science engineering professional development for K-12 educators. 2011 ASEE Annual Conference & Exposition Vancouver, BC: 22.1019.1–22.1019.15. doi: 10.18260/1-2–18288

Download this article as a PDF