Making laser flashes meet their mark Understand article

Take a closer look at the construction of European XFEL.

In the German city of Hamburg, scientists and engineers are assembling a subterranean super microscope capable of seeing matter in motion using X-ray laser flashes. Smaller structures, faster movements, more intense light: European XFEL will open up areas of research that were previously inaccessiblew1. But scientists have to make sure these flashes, travelling down a kilometres-long path, can accurately meet a tiny object such as a biomolecule or a living cell as precisely as possible several thousand times per second. Look inside two of the myriad technical advances making this possible.

European XFEL will use X-ray laser flashes that last for a few femtoseconds (10-15 s) to investigate matter down to the atomic level, at a rate of 27 000 flashes per second. Scientists will use European XFEL to map the atomic details of viruses, decipher the molecular composition of cells, take 3D images of the nanoworld, film chemical reactions, and study processes such as those occurring deep inside planets. But before the first such molecular movie can be shot, scientists and engineers have to make sure the flashes and the things they want to study meet in the right place at the right time. This requires technological developments in two key areas:

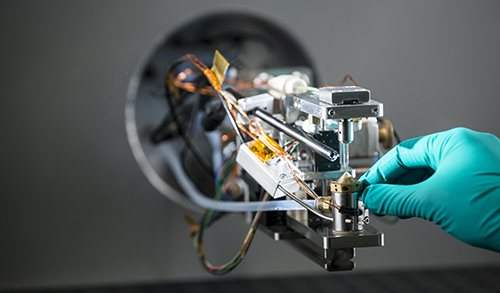

Image courtesy of European XFEL

- To direct the X-rays to their targets while preserving their special laser properties, scientists need the flattest mirrors ever made.

- To study nanostructures, they need a sample delivery system that is not only ultrafast but also able to easily isolate objects ranging in size from cells to biomolecules.

To attain these extremes of size and speed, scientists need to advance technology beyond the current state of the art.

Unimaginably flat

Image courtesy of European

XFEL

From where they first originate, the X-ray laser flashes of European XFEL have a long journey to the facility’s experiment hall. To generate the X-rays, scientists accelerate electrons to very high energies. They do this by getting the electrons to move at nearly the speed of light in a 2 km long superconducting accelerator that has been cooled to 2 Kelvin, just two degrees above absolute zero. The electrons then pass through a series of alternating magnets called undulators. With each change of direction, the electrons emit X-ray light as they zigzag along between the magnets. The interaction of the electrons with the generated light causes that light to be laser-like, or coherent, with all of its photons having the same wavelength and being in phase with one another.

Redirecting X-ray laser light that has such specific properties isn’t easy: you need mirrors that are flatter than we might consider flat. A still lake with no disturbances in its surface may appear to be a perfectly flat mirror, but it has the same curvature as the planet and may have waves that are too small to see. The same applies to everyday mirrors that you’d find in your house. Using a mirror of such curvature and roughness would increase the fuzziness of the beam beyond its useful limit. Even the roughness of superflat mirrors used for telescopes (which are within a few micrometres of flatness) is still enough to negatively affect the X-ray laser light. X-ray free-electron lasers need mirrors roughly fifty times smoother than those used for telescopes.

To solve the problem, European XFEL scientists designed a mirror made from a 1 m long block of silicon, polished to within approximately 2 nanometres of perfect flatness. That’s the same as a road being 28 km long and going up or down by only the width of a human hair for its entire length. Additionally, scientists will be able to alter the shape of the beam using an ultrafine responsive motor system that will flex the mirror by nanometres.

“With the advancements we’ve made with mirror polishing and metrology, I have a good feeling,” says Maurizio Vannoni, one of the scientists involved with the development of European XFEL’s optical components. “We wanted something dependable for our first light [experiment] in 2017, and I’m confident we will have it.”

Special delivery

More technological advancements are underway to make sure that the samples for study meet the laser flashes as accurately as possible.

Scientists from around the world will be using European XFEL’s six scientific instruments to study everything from viruses and tiny crystals of biomolecules to nanoparticles and plasmas. With the X-ray laser’s 27 000 flashes per second, scientists have to ensure their samples are at the exact right spot at the exact right time without any prior treatment.

To acquire data, the scientists will scatter X-ray flashes off an isolated sample and into a detector. For example, if studying a virus, each viral particle would have to reliably pass a tiny target area at a rate that allows it to be hit with several of the incoming X-ray flashes.

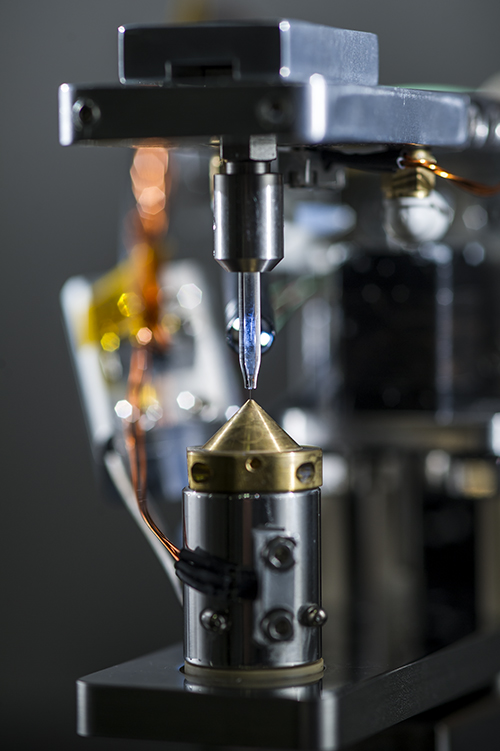

showing the thin liquid jet

Image courtesy of European

XFEL

By using a stream of liquid only a micrometre in diameter, scientists at European XFEL are aiming to place these samples directly into the path of the flashes. This liquid jet is pushed through a specially designed nozzle so that the crystals are delivered at a consistent rate. A separate, more complicated setup is also in development and would deliver uncrystallised biological cells or viral particles. In this instance, the liquid around the samples would be removed using differential pressures and the particles would be steered into position by an electrical field, so that nothing would come between the sample material and the X-ray flashes.

“The challenge is to replace the sample rapidly to get fresh sample with every shot,” says Joachim Schultz, the scientist who leads the sample environment group at European XFEL. “At the same time, we cannot waste too much sample between the shots. There is a lot of effort going into optimising this delivery process.”

These developments are only two of the very many needed to build the European XFEL. Big leaps are being made in other sample delivery methods, ultrafast detector technology, optical laser systems, data acquisition, control software, and many other aspects of this facility of superlatives, which continues to push current technical boundaries so we can see the nanocosmos more clearly than ever.

Web References

- w1 – For more information about European XFEL, see: www.xfel.eu

- The European X-ray Free Electron Laser (European XFEL) is a research facility currently under construction in the Hamburg area in Germany. Its extremely intense X-ray flashes will be used by researchers from all over the world.

Institutions

Review

This article is most useful as a news article about current work in a research lab and could allow the teacher to start a discussion on modern research topics and how European XFEL will be used.

Stuart Farmer, Robert Gordon’s College, Scotland, UK